Supply Chain Strategy Built on Strong Pillars

Experts in EMS strategy, manufacturing readiness, logistics, and site transfers.

Experts in EMS strategy, manufacturing readiness, logistics, and site transfers.

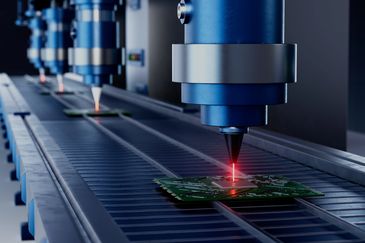

Manufacturing Readiness

From BOM stability and DFx to test coverage and NPI cost clarity, we ensure products are truly manufacturing-ready — delivering speed, flexibility, and seamless transition to low cost regions

EMS Management Strategy

Through transparent pricing, clear contracts, and structured governance, we turn EMS relationships into true partnerships — delivering cost control, performance accountability, and alignment with your goals.

Logistics Optimization

Forward logistics is more than freight. We improve how materials are staged, stored, and handled — ensuring lower costs, less waste, and faster movement through distribution centers.

Refurbishment & Asset Lifecycle

Refurbishment and lifecycle management means controlling returns, repair, and recertification — turning unused or failed units into reliable assets ready for redeployment or resale.

BOM Instability - Unpredictable Yields - Inconsistent NPI Pricing - Undefined Build times - Site Transfer Delays

Hidden Assembly Costs - Weak Supplier Governance - Contract Gaps - Uncontrolled E&O - OTD Misses

High Storage Costs – Inefficient Pick/Pack/Pull – Excess Handling – Missed OTD Targets

Rising Repair Costs – Slow Turnaround – Limited Recertification Control – Low Value Recovery

At Vertical Pillars, we solve these problems with clarity in EMS pricing, discipline in manufacturing readiness, efficient logistics, and lifecycle cost control — strengthening the foundation of your supply chain.

Vertical Pillars is built on a career spanning more than two decades in manufacturing and supply chain leadership. Our founder, Anthony Gonzales (pictured left), has managed every stage of the product lifecycle — from early new product introduction and factory readiness to global EMS partnerships, forward and reverse logistics, and end-to-end supply chain operations.

Throughout his career, Anthony has worked with some of the world’s most innovative companies across semiconductors, networking, enterprise storage, and consumer electronics. His experience covers products ranging from advanced wafer inspection tools and networking hardware to breakthrough consumer devices that redefined digital entertainment. Along the way, he has led teams across program management, procurement, engineering, planning, and operations — consistently driving faster launches, cost clarity, and resilient supply chains.

This depth of experience allows Vertical Pillars to combine strategic insight with practical execution, helping OEMs solve today’s most pressing challenges in EMS management, manufacturing readiness, logistics, and lifecycle strategy.

When a leading aerospace manufacturer struggled with opaque EMS pricing and poor supplier accountability, they turned to Vertical Pillars. Through targeted contract analysis, pricing reviews, and supplier engagement, we uncovered hidden costs, enforced governance discipline, and reduced inflated assembly lead times — positioning the client for sustainable growth.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.